About us

NAIDY was founded in 1997 as a company that produced cabinet furniture. This direction gave the company a good start in furniture business. Cabinet furniture production direction is currently developing successfully, furniture plant NAIDY-FURNITURE has a leading position on the furniture market in Izhevsk and the Udmurt Republic. Furniture, kitchens, rolling door wardrobes from have become the synonyms of the words quality, comfort, reliability and unique interior of your home.

When NAIDY-FURNITURE plant started working, we found several disadvantages of the Russian furniture market:

- No furniture fittings manufacturers in Russia,

- Low quality of furniture fittings,

- High percentage of foreign components in the furniture.

A year later, in 1998, the company’s management makes a decision to start manufacturing several furniture components at the newly opened in Izhevsk manufacturing plant.

- Steel NAIDY system for rolling door wardrobes;

- Plastic furniture fittings;

- Manufacture of net shelves and net baskets for rolling door wardrobes;

- Wardrobe systems and many other things.

Already in 2001 NAIDY was providing NAIDY-FURNITURE plant with 70% of its own-produced furniture fittings and went outside the territory of Izhevsk and the Udmurt Republic. Rolling door wardrobes components were delivered all over Russia, from Murmansk to Makhachkala, from Kaliningrad to Khabarovsk.

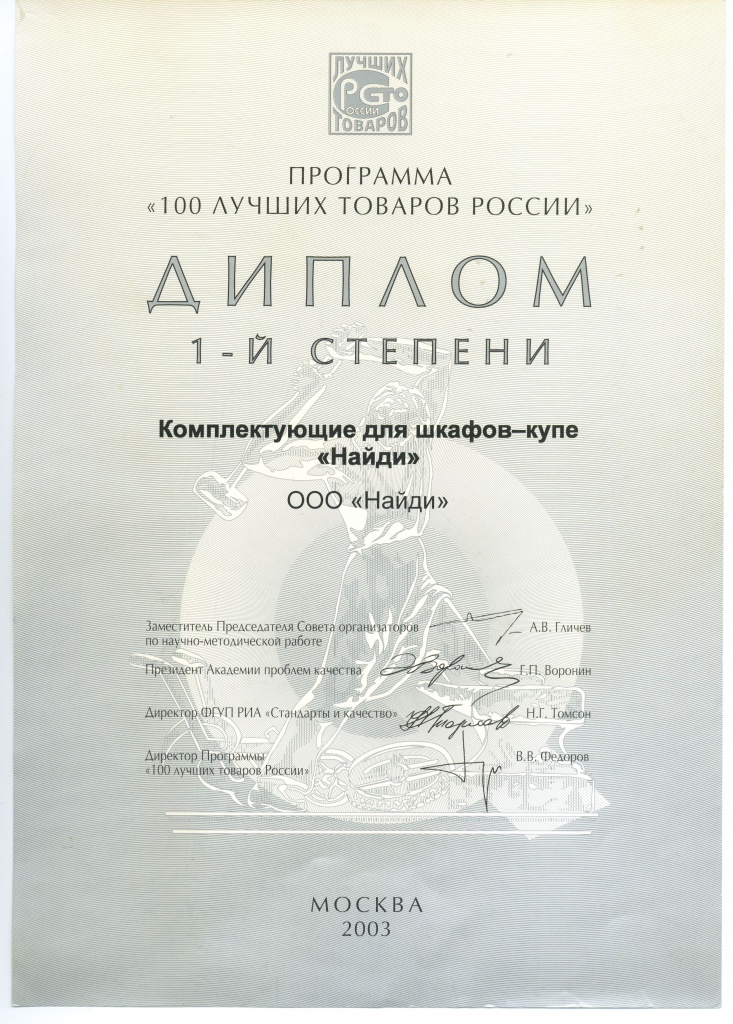

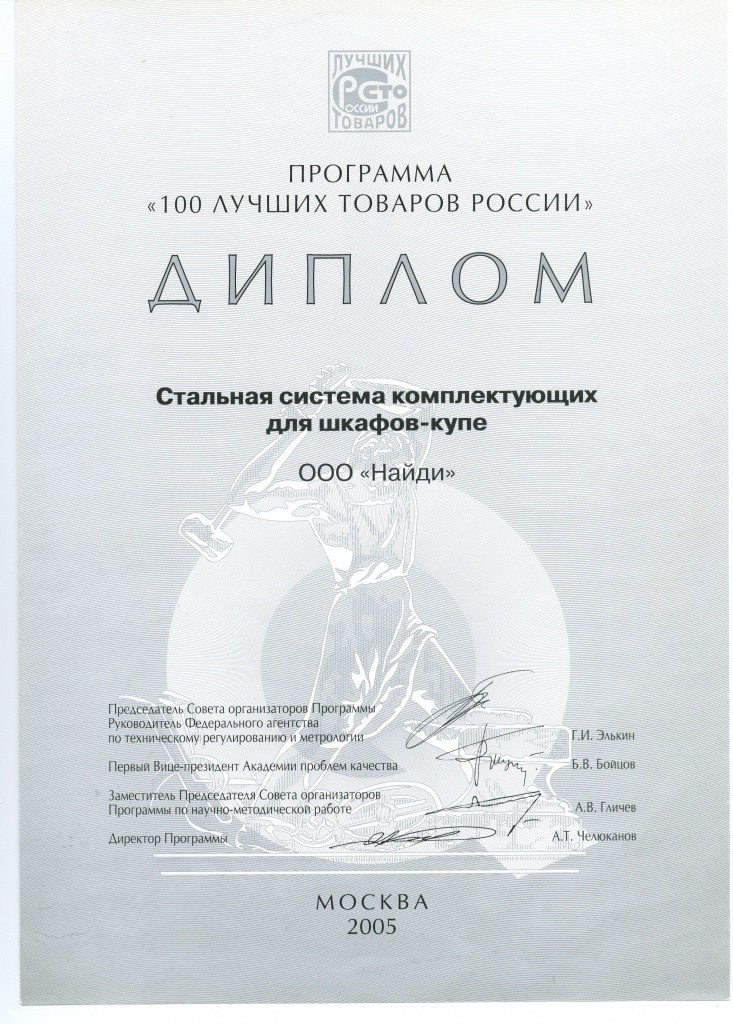

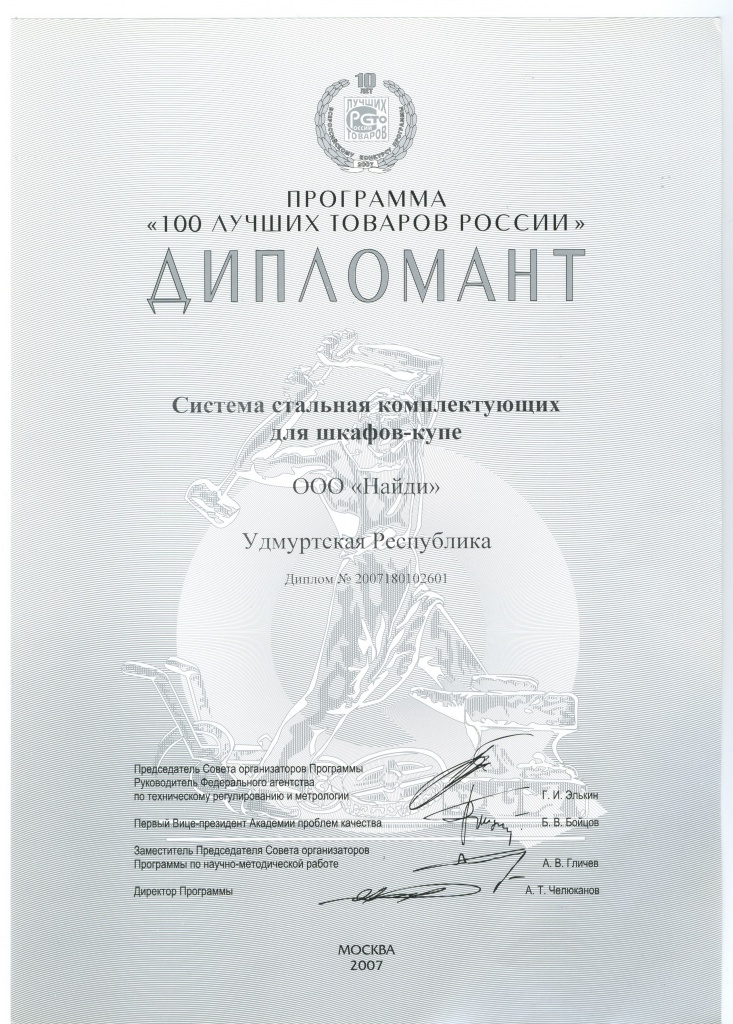

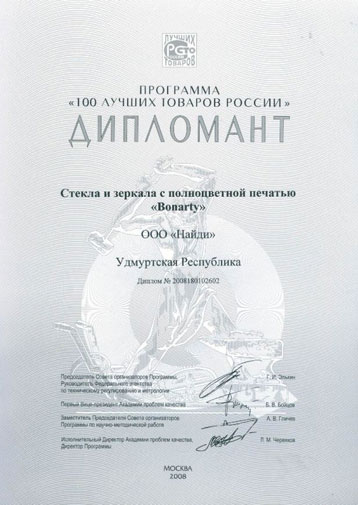

Our Design Engineering Department was designing products that furniture-makers needed the most. Based on many years of experience, company’s specialists always try to evaluate advantages and disadvantages of different similar systems when they are developing the new product, they find their inspiration on international exhibitions choosing the best ideas and approved constructions trying to correct all the mistakes made by the competitors. Our products are highly evaluated by our clients, furniture-makers and deservingly win diplomas of different exhibitions as well as the competition “100 best goods of Russia”:

2003 NAIDY components for rolling door wardrobes

2005 NAIDY steel system

2007 NAIDY steel system

2008 NAIDY net storage systems

2008 Glass and mirrors with full-colour printing BONARTY

We were mastering the new products and starting the new manufacturing sites, so the necessity arose to put the different sites together under one roof. We chose a site in 2007 and started building a plant that would manufacture furniture components. In 2009 we opened: «NAIDY Furniture Components Manufacture Plant»:

- Total area more than 11 000 square metres;

- Company head office – 1 500 square metres;

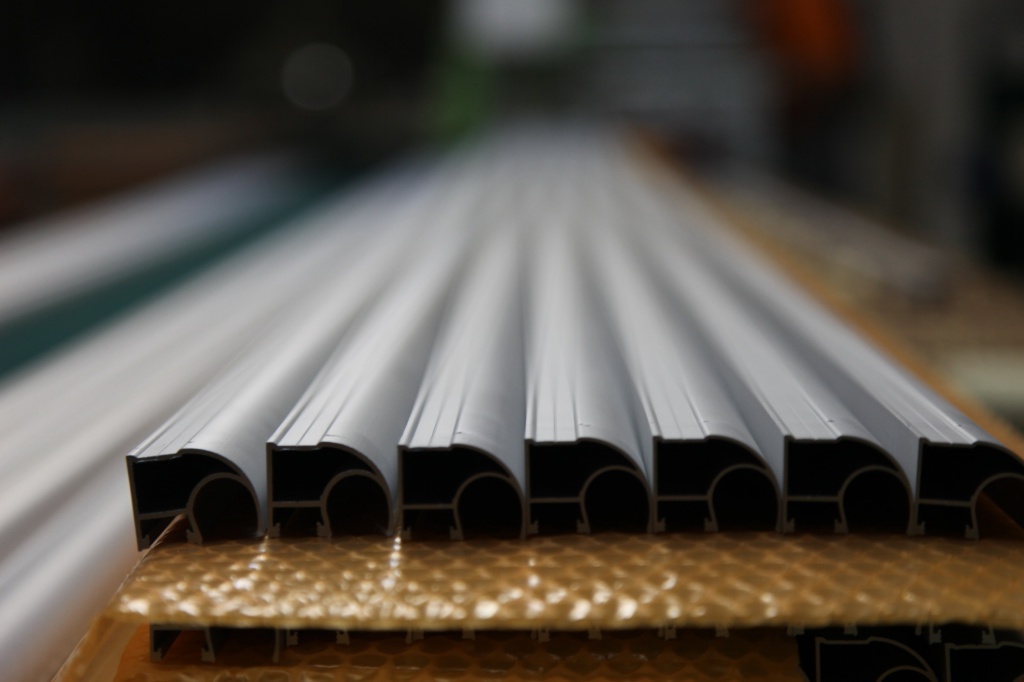

- Automatic line of steel profile production;

- Punching and metalwork section;

- Section of moulding of plastics under pressure;

- Net products manufacture section;

- Powder coating line;

- Glass processing section;

- Aluminium profile envelopment section;

- More than 200 blue and white collar workers.

All sites were equipped with the modern, high technology equipment.

After opening NAIDY Furniture Components Manufacture Plant, enterprise performance was certified for compliance of quality management system with the standard ISO 9001. We also successfully completed the certification of rolling door wardrobes and NAIDY-FURNITURE plant for compliance with Russian National Standard.

Additionally to expanding our production, in 2006 NAIDY presented NAIDY Aluminium system for rolling door wardrobes on the second international Furniture Club exhibition in an international exhibition center Crocus Expo. The system, manufactured in China, quickly became popular on the Russian furniture market. NAIDY suspended aluminium system for nonthreshold connecting doors and interior partitions.

In 2010 we started building an aluminium profile anodising plant. We finished building such a big object in 1,5 years, aluminium profile anodising plant was opened in 2011:

- Total area more than 15 000 square metres;

- Aluminium profile shot blasting section;

- Aluminium profile anodising automatic line;

- Aluminium profile electrocolouring bath tubs;

- Aluminium profile gloss (laquer) coating application bath tubs;

- Decoration section (thermal transfer) – wood texture application on an aluminium profile;

- Punching, cutting and metalwork section.

Plant rated capacity – 350 tonnes of anodised aluminium profile a month.

After opening its own profile anodising plant and organizing the logistics with aluminium profile compression operator NAIDY got an opportunity to complete orders of any size within a short time (3-4 weeks) as well as produce aluminium profile based on customers’ drawings.

In the same year a line of kitchen profiles was added into the company’s assortment: five nominal sizes of edge aluminium profiles and three façade profiles.

Izhevsk anodising plant opening allowed to develop and produce a new product for the Russian market – aluminium profile furniture stand legs for tables. NAIDY developed full furniture fittings kit for glass tables as well as plates material tables. All the necessary furniture fittings are manufactured on NAIDY Furniture Components Manufacture Plant. NAIDY furniture stand legs offer has no equals not only in Russia but also in Europe:

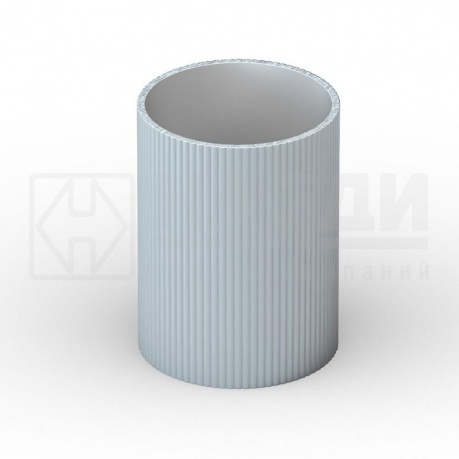

- Three aluminium profile configurations: round, square, triangle;

- Rippled furniture stand legs;

- Four colour solutions;

- Full furniture fittings kit;

- Convenient packaging;

- Profitable price.

NAIDY keeps moving forward, in 2014 we bring storage system Home Space to the market. Home Space is a storage system for your home based on net baskets and net shelves fixed on a vertical assembly stand. Convenient, light and simple to assemble such constructions are in steady demand among customers.

The system was presented on a FURNITURE exhibition in Moscow in 2014 and was highly evaluated by our long-standing partners and the exhibition’s visitors. Main advantages of the system compared to the analogues are: reliability, high functionality, available price.

In 2017 we made a decision to launch an online shop aimed at bulk as well as retail customers. At people who don’t want to buy the products in bulk, they want small batches, maybe even buying “for themselves”.

In 2018 the company launched a new product line – gardening products. First samples of high garden beds were produced and installed in gardens to test them in real weather conditions. Production technology was adjusted, packaging and video instructions were developed and in 2019 we entered the market!

One more direction: frame-module system Loft Kit started in 2019. Ready-made kits of the system products became popular on international furniture exhibitions: Furniture-2019 in Moscow, IMM Cologne in Cologne, Germany.

From season to season we keep developing and presenting new kits that increase the opportunities of the system.

Each item goes through several preparation stages before entering the market: configuration, packaging, instructions and technical information creation, market promotion.

Our main goal is to make our customers happy –

from furniture manufacturers to ultimate customers.

We are looking for cooperation with:

- Furniture companies

- Internet media

- Interior designers

For you we can create an individual

Loft style furniture line!